Introduction

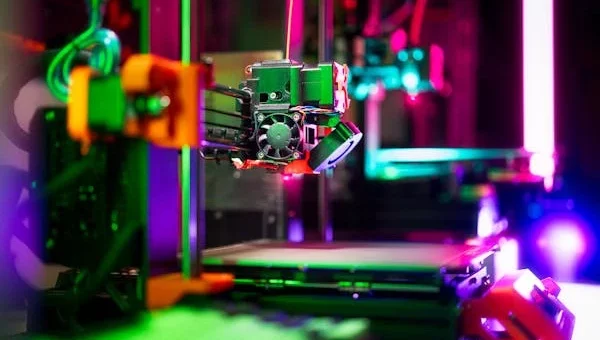

The aerospace industry has always been at the forefront of adopting cutting-edge technologies to enhance performance, efficiency, and innovation. Among these technologies, 3D printing — also known as additive manufacturing — is rapidly transforming how fighter jets are designed and built. This shift is not just about creating parts faster; it’s about reshaping the entire production process, allowing unprecedented levels of customization, cost efficiency, and rapid prototyping.

In this comprehensive article, we explore how 3D printing is becoming a game changer in fighter jet production. We will discuss the technology’s fundamentals, its benefits and challenges, real-world applications, and its implications for the future of aerospace defense manufacturing.

Table of Contents

-

Understanding 3D Printing in Aerospace

1.1 What is 3D Printing?

1.2 Types of 3D Printing Technologies Used in Aerospace -

Advantages of 3D Printing in Fighter Jet Production

2.1 Design Flexibility and Innovation

2.2 Cost Reduction and Resource Efficiency

2.3 Accelerated Production Timelines -

Applications of 3D Printing in Fighter Jets

3.1 Structural Components

3.2 Engine Parts

3.3 Maintenance and Repair -

Challenges and Limitations

4.1 Material Constraints

4.2 Certification and Safety Standards

4.3 Scalability Concerns -

The Future of 3D Printing in Fighter Jet Manufacturing

5.1 Integration with AI and Digital Twins

5.2 Potential for On-Demand Manufacturing

5.3 Environmental Impact and Sustainability -

Conclusion: Is 3D Printing a True Game Changer?

1. Understanding 3D Printing in Aerospace

1.1 What is 3D Printing?

3D printing, or additive manufacturing, is a process that builds objects layer by layer from digital models. Unlike traditional subtractive manufacturing, which involves cutting or machining parts from raw materials, 3D printing allows complex geometries to be created with minimal waste. This technology has evolved from creating prototypes to producing functional end-use parts, especially in high-precision industries like aerospace.

In fighter jet production, 3D printing enables engineers to produce lightweight, robust components that were previously impossible or too costly to manufacture. By depositing material layer upon layer, manufacturers can optimize parts for performance and weight without compromising structural integrity.

1.2 Types of 3D Printing Technologies Used in Aerospace

Several 3D printing technologies have found applications in aerospace manufacturing, particularly in fighter jets:

-

Selective Laser Melting (SLM): Uses a high-powered laser to fuse metal powders, creating dense, high-strength parts suitable for structural components.

-

Electron Beam Melting (EBM): Similar to SLM but uses an electron beam, ideal for titanium alloys commonly used in aerospace.

-

Direct Metal Laser Sintering (DMLS): Another metal 3D printing method offering precision and excellent mechanical properties.

-

Fused Deposition Modeling (FDM): Primarily for rapid prototyping and non-critical parts using thermoplastics.

These technologies enable the creation of parts with complex internal structures, reducing weight while maintaining strength, which is critical for fighter jet performance.

2. Advantages of 3D Printing in Fighter Jet Production

2.1 Design Flexibility and Innovation

One of the most significant advantages of 3D printing is the freedom it provides in design. Engineers can create complex shapes, internal lattices, and integrated components that reduce assembly needs. This design freedom leads to:

-

Weight reduction: Lighter parts improve jet agility and fuel efficiency.

-

Part consolidation: Multiple components can be combined into a single printed part, reducing assembly time and potential points of failure.

-

Rapid prototyping: Iterative testing and design improvements accelerate innovation cycles.

For instance, fighter jet manufacturers have developed 3D printed brackets and ducts with intricate geometries that traditional manufacturing methods cannot produce.

2.2 Cost Reduction and Resource Efficiency

Traditional aerospace manufacturing involves expensive tooling, molds, and extensive machining, often producing significant material waste. 3D printing addresses these cost drivers by:

-

Reducing waste: Additive manufacturing uses only the necessary material, significantly cutting down on scrap.

-

Lower tooling costs: No molds or special tooling are required, making low-volume production economically viable.

-

Inventory reduction: On-demand production of parts reduces the need for large inventories and warehousing.

Example:

| Cost Factor | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Material Waste | High | Low |

| Tooling & Setup | Expensive & Time-Consuming | Minimal |

| Lead Time | Weeks to Months | Days to Weeks |

| Inventory Costs | High | Reduced |

2.3 Accelerated Production Timelines

Speed is critical in defense manufacturing, where rapid deployment can be a strategic advantage. 3D printing enables:

-

Faster prototyping: New designs can be printed and tested within days instead of weeks.

-

Quicker spare parts production: Critical parts can be printed on demand, reducing aircraft downtime.

-

Streamlined supply chains: Less dependency on multiple suppliers shortens procurement cycles.

This agility is transforming maintenance, repair, and overhaul (MRO) operations by enabling field or depot-level 3D printing of replacement components.

3. Applications of 3D Printing in Fighter Jets

3.1 Structural Components

3D printing is increasingly used to manufacture structural parts like brackets, air ducts, and mounting fixtures. These components benefit from:

-

Complex geometries that improve airflow and reduce weight.

-

Material properties tailored through printing parameters to ensure strength and durability.

Examples include 3D printed titanium brackets used in the F-35 Lightning II, which reduced part count and weight while maintaining performance standards.

3.2 Engine Parts

Engines demand parts with high thermal resistance and precision. Additive manufacturing allows:

-

Production of cooling channels within turbine blades that are impossible with conventional methods.

-

Rapid replacement parts that maintain strict tolerances and material integrity.

GE Aviation, for example, uses 3D printing for jet engine fuel nozzles, achieving a 25% weight reduction and improved durability.

3.3 Maintenance and Repair

MRO is a critical area where 3D printing impacts fighter jet readiness:

-

On-site printing: Enables rapid production of obsolete or rare parts at maintenance facilities.

-

Customization: Repair parts can be tailored to specific wear patterns or damage profiles.

-

Cost savings: Reduces logistics and shipping expenses by localizing production.

Military bases have begun deploying mobile 3D printing units to support front-line aircraft maintenance.

4. Challenges and Limitations

4.1 Material Constraints

While 3D printing metal alloys is advancing, material choices remain limited compared to traditional manufacturing. Issues include:

-

Material homogeneity: Ensuring uniform mechanical properties throughout the part.

-

Anisotropy: Parts may have different strength characteristics depending on print orientation.

-

Material certification: Limited data on long-term performance under combat conditions.

Ongoing research is focused on expanding printable materials and improving consistency.

4.2 Certification and Safety Standards

Aerospace parts must meet rigorous certification standards for safety and reliability. Challenges for 3D printed parts include:

-

Qualification processes: Each part design and printing process requires validation.

-

Regulatory hurdles: Certification agencies are still developing standards specific to additive manufacturing.

-

Traceability: Documenting the entire print process for quality assurance.

These factors slow widespread adoption but progress steadily as standards mature.

4.3 Scalability Concerns

Despite advantages, 3D printing currently struggles with:

-

Large-scale production: Printing every part of a fighter jet is impractical today due to speed and cost.

-

Size limitations: Printer build volumes restrict part dimensions, requiring assembly of multiple printed components.

-

Equipment costs: Industrial-grade 3D printers require significant capital investment.

Manufacturers often use hybrid approaches combining 3D printing with traditional methods.

5. The Future of 3D Printing in Fighter Jet Manufacturing

5.1 Integration with AI and Digital Twins

Artificial intelligence (AI) and digital twin technology complement 3D printing by enabling:

-

Optimized designs: AI algorithms generate lightweight structures tailored to mission profiles.

-

Predictive maintenance: Digital twins simulate part behavior to forecast wear and schedule replacements.

-

Adaptive manufacturing: Real-time data adjusts printing parameters for quality control.

This synergy promises smarter, more resilient fighter jets.

5.2 Potential for On-Demand Manufacturing

On-demand manufacturing at military bases or even deployed locations could revolutionize logistics by:

-

Reducing supply chain vulnerabilities and dependence on global suppliers.

-

Enhancing operational readiness through rapid part availability.

-

Customizing parts for unique mission environments.

Efforts are underway to develop portable, rugged 3D printers for field use.

5.3 Environmental Impact and Sustainability

3D printing offers sustainability benefits crucial for future aerospace:

-

Reduced waste through additive layering.

-

Energy savings by cutting machining and transportation needs.

-

Use of recycled materials and eco-friendly powders.

Sustainability is becoming a key consideration in defense manufacturing strategies.

Conclusion: Is 3D Printing a True Game Changer?

3D printing is undeniably reshaping fighter jet production, introducing new capabilities in design, manufacturing speed, and cost efficiency. While challenges remain — especially regarding materials, certification, and scalability — ongoing technological advances are steadily overcoming these hurdles.

The ability to rapidly prototype, produce complex parts, and localize manufacturing holds profound strategic value for aerospace defense. As additive manufacturing becomes more integrated with AI, digital twins, and sustainable practices, its role will only expand.